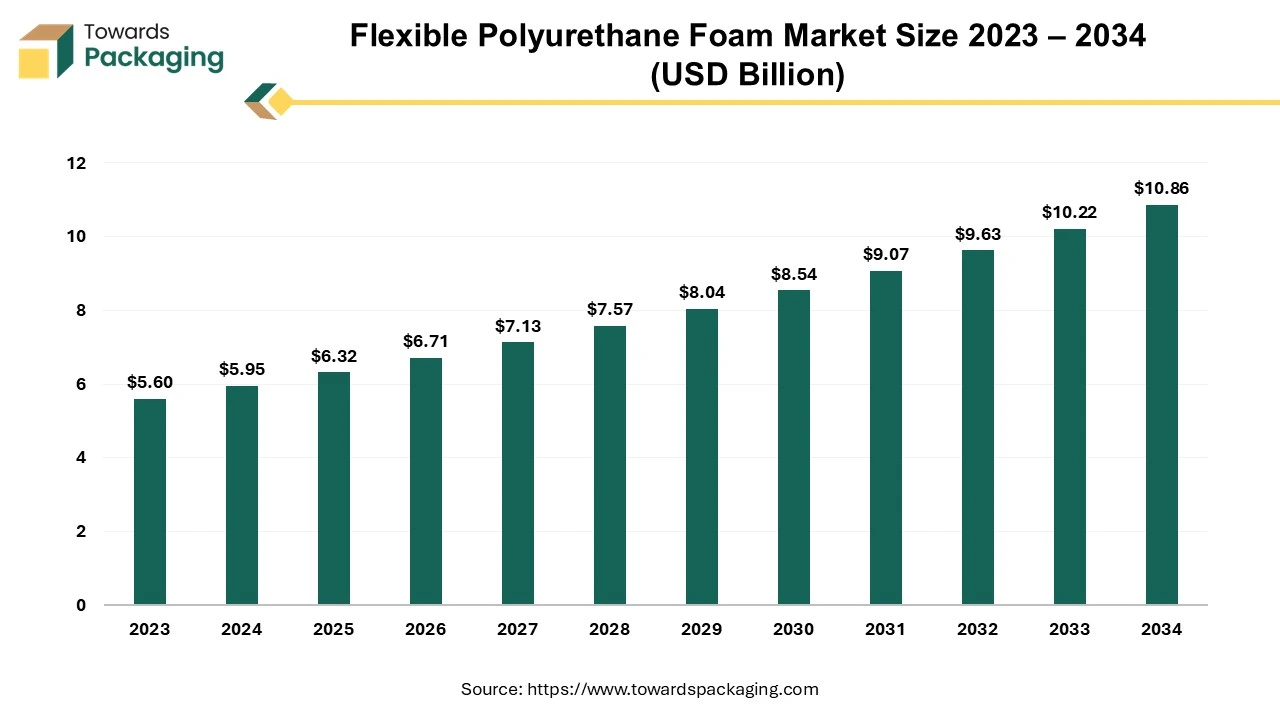

Flexible Polyurethane Foam Market Size to Strike USD 10.86 Bn by 2034

The flexible polyurethane foam market size stood at US$ 5.95 billion in 2024 and is predicted to exceed US$ 10.86 billion by 2034, experiencing a CAGR of 6.20% from 2024 to 2034.

/EIN News/ -- Ottawa, April 10, 2025 (GLOBE NEWSWIRE) -- The flexible polyurethane foam market size to record US$ 6.32 billion in 2025 and is projected to grow beyond US$ 10.86 billion by 2034, a study published by Towards Packaging a sister firm of Precedence Research. The key players operating in the market are focused on adopting inorganic growth strategies like acquisition and collaboration to develop new technology for flexible polyurethane foam, which has estimated to drive the growth of the flexible polyurethane foam market in the near future.

Get All the Details in Our Solutions – Download Brochure: https://www.towardspackaging.com/download-brochure/5418

Market Overview

The polymer material manufactured by reacting a polyol (a type of alcohol with multiple hydroxyl groups) with an isocyanate, usually in the presence of catalysts, surfactants, blowing agents, and other additives is referred to as flexible polyurethane foam (FPF). Flexible Polyurethane Foam (FPF) is part of the larger family of polyurethane foams, which can range from very soft and flexible to rigid and hard, depending on the formulation. Flexible polyurethane foam is specifically engineered for softness, elasticity, and cushioning properties.

The chemical composition of flexible polyurethane foam are polyols, isocyanates, blowing agents, catalysts, surfactants, and additives. The flexible polyurethane foam (FPF) is lightweight, comfortable, durable, thermal insulation, and customizable. The flexible polyurethane foam (FPF) can dampen sound making it useful in noise-reducing applications. The flexible polyurethane foam is extremely versatile and is utilized in many industries like furniture, bedding, automotive, packaging, footwear, textiles, acoustic panels, and medical. The flexible polyurethane is used in hospital beds, wheelchair, cushions, orthotic supports.

Major Key Trends in flexible polyurethane foam Market

Smart Foam:

Integration of the flexible polyurethane foam with sensors for pressure mapping and health monitoring. The innovative technology known as SmartFoam is exclusive to AlwaysFlexProtect feminine sanitary towels. This foam is incredibly soft and absorbent. Fluid may be swiftly drawn from the sanitary towel's top layer deep into the bottom layer, where it is kept, due to its layered construction. Smart foam significantly lowers energy and water usage. Water savings of up to 80% are possible when chemicals are applied using smart foam as opposed to conventional washing methods.

Advanced Formulations:

Innovations for higher performance (e.g., temperature-regulating foams). In order to produce foams that can absorb and release heat, increasing thermal comfort and energy efficiency, sophisticated formulations for temperature-regulating foams are being created. These formulations frequently include components like phase change materials (PCMs) or nanoparticles.

Aerospace and Automotive Growth:

As the flexible polyurethane foam (FPF) is lightweight it is extensively used in vehicles. Flexible polyurethane foam (FPF) is widely used in automotive and aerospace industries because it meets a unique combination of demands that these sectors require: cost-effectiveness, design flexibility, comfort, weight reduction, and safety. Both automotive and aerospace industries are obsessed with reducing weight to improve fuel efficiency (for cars) and fuel economy (for aircraft). Flexible Polyurethane Foam (FPF) has a very low density but retains strength and cushioning, making it ideal for reducing overall vehicle weight without compromising on comfort or safety.

In aerospace, where every gram matters, lightweight materials directly impact operating costs. Flexible polyurethane foam (FPF) is soft yet supportive, making it perfect for seating systems. In automobiles, it’s used in car seats, armrests, headrests — providing long-term comfort for drivers and passengers, especially on long journeys. Flexible polyurethane foam (FPF) acts as an excellent sound dampener and vibration isolator. In cars, it reduces road noise and engine vibrations inside the cabin.

If there's anything you'd like to ask, feel free to get in touch with us @ sales@towardspackaging.com

Limitations & Challenges in Flexible Polyurethane Foam Market:

Environmental Regulations & Concerns

Traditional FPF is derived from petrochemical sources (polyols and isocyanates), contributing to fossil fuel consumption and carbon emissions. Flexible Polyurethane Foam (FPF) can emit volatile organic compounds (VOCs), which are linked to indoor air quality issues and health concerns (like eye and respiratory irritation). Increasing environmental regulations (like REACH in Europe, or EPA regulations in the U.S.) are tightening control over chemicals used in FPF production. Flexible Polyurethane Foam (FPF) is not biodegradable, and while recycling is possible, it remains limited. Disposal often ends in landfills or incineration, raising sustainability issues.

Availability of Alternatives

The latex foam, coconut coir, and bio-based polyols are gaining traction as eco-friendlier alternatives. Viscoelastic foams (still polyurethane-based but different formulation) and gel-infused foams offer superior comfort, temperature control, and durability. Thermoplastic elastomer (TPE) foams are emerging as fully recyclable substitutes for some applications.

Market Saturation & High Competition

The furniture and automotive markets, two of the biggest consumers of FPF, are already mature and highly competitive. Manufacturers are under constant price pressure, limiting profit margins and making it difficult to invest in innovation or sustainability transitions.

Growing Use in Packaging Solutions to Drive the Market

The e-commerce expansion is driving demand for protective packaging. The flexible polyurethane foam is extensively utilized for fragile items, high-value goods, and electronics. Custom-molded foam inserts and protective solutions are becoming mostly utilized. Development of sustainable flexible polyurethane foam packaging for high-growth e-commerce sectors, has estimated to create lucrative opportunity for the growth of the flexible polyurethane foam market in the near future.

- For instance, in November 2024, At the Spring Meeting of the Polyurethane Foam Association in New Orleans, individuals from over a dozen nations convened to deliberate on matters impacting the flexible polyurethane foam sector.

Regional Analysis:

Asia’s Expanding Automotive Industry to Promote Dominance

Asia Pacific region held the largest share of the flexible polyurethane foam market in 2024, driven by the expanding automotive industry in the region. Countries like China, India, Japan, South Korea, and ASEAN countries are major automotive hubs. Growing middle-class population and rising vehicle ownership drive high demand for comfort-oriented automotive interiors — seats, headrests, armrests, sound insulation, etc. The shift toward electric vehicles (EVs) also fuels demand, as lightweight FPF helps improve EV efficiency and range. Asia Pacific is experiencing massive urbanization, with huge investments in infrastructure and housing.

Countries like India and China have ambitious housing and smart city development plans, directly increasing FPF consumption. The growing hospitality sector (hotels, resorts) across Southeast Asia and China boosts demand for FPF in bedding and seating applications. Asia Pacific is a global manufacturing hub for electronics, especially in China, South Korea, Japan, and Vietnam. Lower labor costs and availability of raw materials (like petrochemicals in China and Southeast Asia) make Asia Pacific a cost-efficient manufacturing base. Many global FPF manufacturers have set up or expanded their operations in Asia to leverage these benefits.

Flexible Material Trends in China

China flexible polyurethane foam market is driven by the automotive and electronic industries in China country. China is a global manufacturing hub for electronics, furniture, automotive and mattresses, supplying both domestic and international markets. China produces a massive share of the world’s consumer electronics, like smartphones, computers, and home appliances. Expansion of China’s electronics sector directly fuels demand for FPF in packaging and internal insulation.

India Market Trends

Indian flexible polyurethane foam market is driven due to well-established chemical manufacturing ecosystem, ensuring steady and cost-effective supply of raw materials like isocyanates and polyols.

Join now to access the latest packaging in dustry segmentation insights with our Annual Membership: https://www.towardspackaging.com/get-an-annual-membership

North America’s Vivid Industrial Sector to Support Growth

North America region is seen to grow at the fastest rate in the flexible polyurethane foam market during the forecast period. North America is indeed a major, established leader in the flexible polyurethane foam (FPF) market globally, particularly with a mature industry structure and innovation edge. North America, especially the U.S. and Mexico, has a highly developed automotive sector. Flexible polyurethane foam is widely used in automotive seating, headrests, armrests, soundproofing, and insulation. The U.S. market demands high comfort and safety standards in vehicles, increasing the per-unit usage of premium FPF. Electric vehicle (EV) growth, led by companies like Tesla and new entrants, boosts demand for lightweight, energy-efficient materials like FPF.

North America enforces strict building codes and energy efficiency standards (like LEED certification and ENERGY STAR programs). North America leads in R&D for advanced polyurethane technologies, including bio-based FPF, low-VOC formulations, and fire-retardant foams. The region benefits from proximity to raw materials (polyols and isocyanates), as North America is a major player in the petrochemical industry. Aging population in the U.S. and Canada drives demand for comfort-oriented healthcare furniture and accessories. North American consumers and businesses are placing increasing emphasis on eco-friendly materials.

Segment Outlook

Application Type Insights

The automotive segment dominated the flexible polyurethane foam market with the largest share in 2024. Flexible Polyurethane Foam (FPF) is lightweight yet durable, which helps manufacturers meet the goal of vehicle weight reduction. Weight savings are crucial for improving fuel efficiency and extending range in electric vehicles (EVs). Lightweight materials are also easier to handle during assembly and reduce shipping costs. FPF is excellent at absorbing noise and vibration, contributing to a quiet and smooth ride. Flexible Polyurethane Foam (FPF) enhances occupant safety by providing impact absorption in seats, headrests, and interior components.

Flexible Polyurethane Foam (FPF) is used in battery pack cushioning, thermal management, and vibration damping in EV platforms. Flexible Polyurethane Foam (FPF) is highly moldable, allowing for customized shapes, textures, and firmness levels. FPF offers a favorable cost-to-performance ratio, making it economical for mass production. Flexible Polyurethane Foam provides long-lasting performance, retaining shape and comfort over years of use. FPF producers are developing low-emission, eco-friendly formulations to align with global regulations.

The aviation segment is anticipated to witness lucrative growth during the forecast period. In aviation, every kilogram matters. Reducing weight leads to significant fuel savings and lower emissions. Flexible Polyurethane Foam (FPF) is extremely lightweight yet durable, making it perfect for seats, cabin panels, headrests, armrests, and insulation. Passengers expect higher levels of comfort for both short-haul and long-haul flights. Airlines and aircraft manufacturers are investing in premium seating solutions (business and first-class), which use advanced FPF technologies.

Foams must comply with regulations from bodies like FAA (Federal Aviation Administration) and EASA (European Union Aviation Safety Agency). Aviation-grade FPF is engineered to meet rigorous fire, smoke, and toxicity (FST) standards. Aircraft cabins experience significant vibration and noise from engines and airflow. Aviation requires materials that can withstand long service lifespans and frequent use. The global increase in air passenger traffic, particularly in Asia-Pacific and Middle East, is driving new aircraft demand.

Elevate your packaging strategy with Towards Packaging. Enhance efficiency and achieve superior results—schedule a call today: https://www.towardspackaging.com/schedule-meeting

Recent Breakthroughs in Global Flexible Polyurethane Foam Market:

- On March 27, 2025, BASF SE, chemical company revealed the introduction of biomass balancing grades of Elastoflex polyurethane systems, extending its product line for the furniture industry. Together with other BASF locations, including the recently certified Livonia, Michigan site, these mass-balanced goods have earned REDcert2l3) certification. According to BASF North America's Business Director for Polyurethanes, Staci Wegener, BASF North America company is committed in helping customers achieve their sustainability goals. In comparison to traditional polyurethane foam systems, BASF company’s clients will be able to purchase products that use renewable feedstocks instead of fossil fuels, potentially resulting in a much lower product carbon footprint. This is made possible by new biomass balance options.

- In March 2025, JPFL Films, a division of Jindal Poly Films, the largest flexible packaging manufacturer in India, has declared that it is the first company to introduce Biaxially Oriented Polyamide (BOPA) nylon films in the country. JPFL Films has invested INR 120 crore in its cutting-edge Nasik plant. In keeping with the government's "Make in India" campaign, BOPA Nylon Films' launch is a calculated step to support the company's expansion.

More Insights in Towards Packaging:

- Multilayer Flexible Packaging Market Consumer Behavior, Demand and Forecast: https://www.towardspackaging.com/insights/multilayer-flexible-packaging-market-sizing

- Flexible Plastic Pouches Market Recycling Rates and Technologies: https://www.towardspackaging.com/insights/flexible-plastic-pouches-market-sizing

- Medical Flexible Packaging Market Size, Share & Growth Projections: https://www.towardspackaging.com/insights/medical-flexible-packaging-market-sizing

- Flexible Paper Packaging Market Size: USD 82.94 Bn by 2034: https://www.towardspackaging.com/insights/flexible-paper-packaging-market-sizing

- Nutraceutical Flexible Packaging Market Key Business Drivers & Industry Forecast: https://www.towardspackaging.com/insights/nutraceutical-flexible-packaging-market-sizing

- E-commerce Flexible Packaging Market Research Insight 2034: https://www.towardspackaging.com/insights/e-commerce-flexible-packaging-market-sizing

- Flexible Plastic Packaging Market Consumer Insights & Growth Strategies: https://www.towardspackaging.com/insights/flexible-plastic-packaging-market-sizing

- Compostable Flexible Packaging Market Size & Investment Opportunities: https://www.towardspackaging.com/insights/compostable-flexible-packaging-market-sizing

- Metalized Flexible Packaging Market Growth and Import & Export Analysis: https://www.towardspackaging.com/insights/metalized-flexible-packaging-market-size

- Sterile Medical Paper Packaging Market Strategic Growth, Innovation & Investment Trends: https://www.towardspackaging.com/insights/sterile-medical-paper-packaging-market-sizing

Global Flexible Polyurethane Foam Market Segments

By Application

- Automotive

- Seats

- Headrests

- Dashboards & Door Panels (Interior)

- Insulation

- Aviation

- Crew & Cockpit Seating

- Passenger Seats

- Crew Rest Mattress

- Insulation

- Mass Transit

By Region

-

North America

- U.S.

- Canada

-

Europe

- Germany

- UK

- France

- Italy

- Spain

- Sweden

- Denmark

- Norway

-

Asia Pacific

- China

- Japan

- India

- South Korea

- Thailand

-

Latin America

- Brazil

- Mexico

- Argentina

-

Middle East and Africa (MEA)

- South Africa

- UAE

- Saudi Arabia

- Kuwait

Invest in Premium Global Insights @ https://www.towardspackaging.com/price/5418

If you have any questions, please feel free to contact us at sales@towardspackaging.com

About Us

Towards Packaging is a leading global consulting firm specializing in providing comprehensive and strategic research solutions. With a highly skilled and experienced consultant team, we offer a wide range of services designed to empower businesses with valuable insights and actionable recommendations. We stay abreast of the latest industry trends and emerging markets to provide our clients with an unrivalled understanding of their respective sectors. We adhere to rigorous research methodologies, combining primary and secondary research to ensure accuracy and reliability. Our data-driven approach and advanced analytics enable us to unearth actionable insights and make informed recommendations. We are committed to delivering excellence in all our endeavours. Our dedication to quality and continuous improvement has earned us the trust and loyalty of clients worldwide.

Our Trusted Data Partners:

Precedence Research | Statifacts |Towards Automotive | Towards Healthcare | Towards Food and Beverages | Towards Chemical and Materials | Towards Consumer Goods | Towards Dental | Towards EV Solutions | Nova One Advisor | Healthcare Webwire | Packaging Webwire | Automotive Webwire

For Latest Update Follow Us: https://www.linkedin.com/company/towards-packaging/

Distribution channels: Consumer Goods ...

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release